Print production – A guide to finding what you want

There are so many elements of print production that it’s hard to know what you’re asking for when you choose a product. You know what you want the end product to look like, but you’re unsure how to ask for it because you don’t understand the technical jargon used in print production.

Hopefully this guide will help you navigate your way through the world of printing as you try to make the best of your budget.

This is the third in a three-part series where we’ll have a look at some of the processes and materials in print production and break it all down for you.

Part 1 – Printing processes

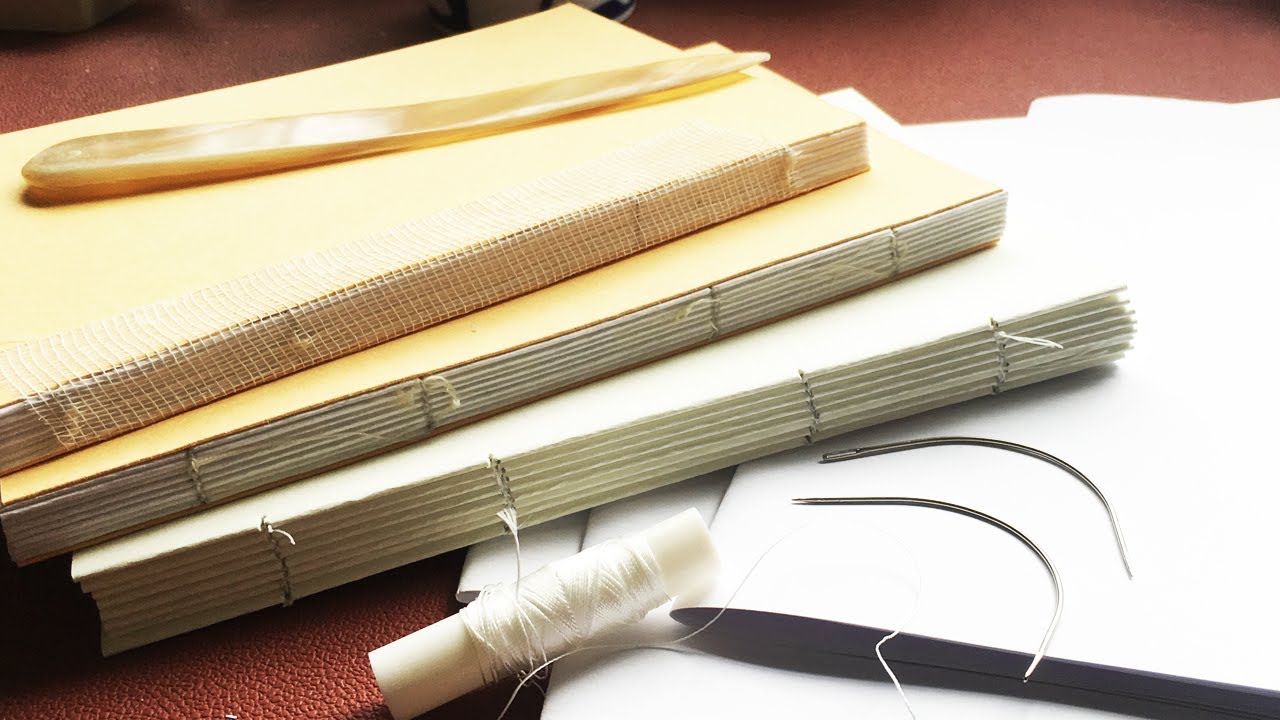

Part 2 – Binding processes

Part 3 – Speciality Finishes (you’re reading this one now!)

Part 3 – Speciality Finishes

Finishing… this word is used describe all sorts of different ways the print product is produced and completed. Everything from actual ‘printing’ to binding, and everything in-between. There are a lot of creative ways to make your brand stand out from the crowd depending on the ‘finishing’ you decide on for your end product. This included the type of print, ink and even binding that you choose.

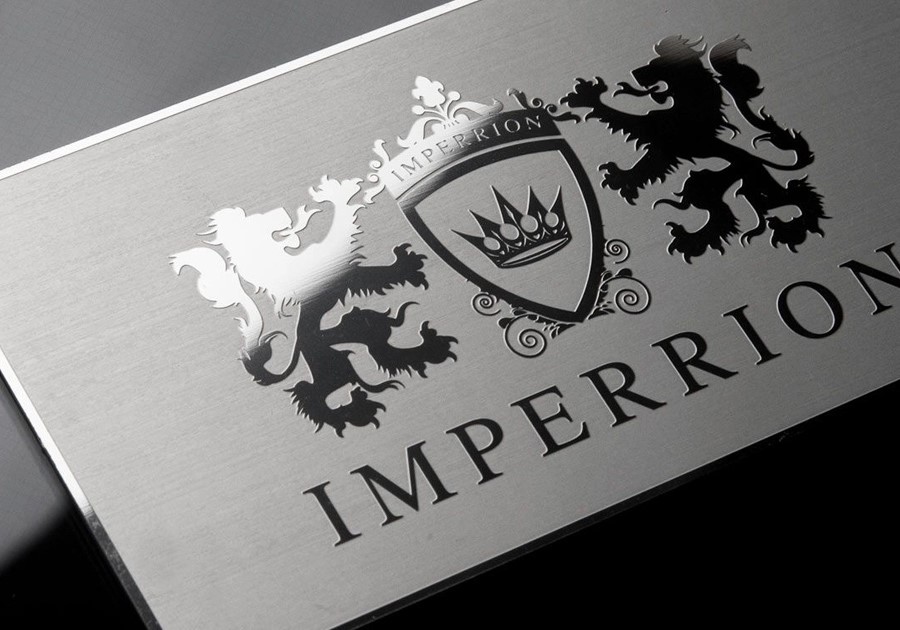

Etching

Etching is a printmaking technique that uses chemicals to create lines in a metal plate, which is then used to hold ink and create an image. It is a traditional method which remains in wide use alongside engraving.

Example of Etching – nameplates, labels, and signage

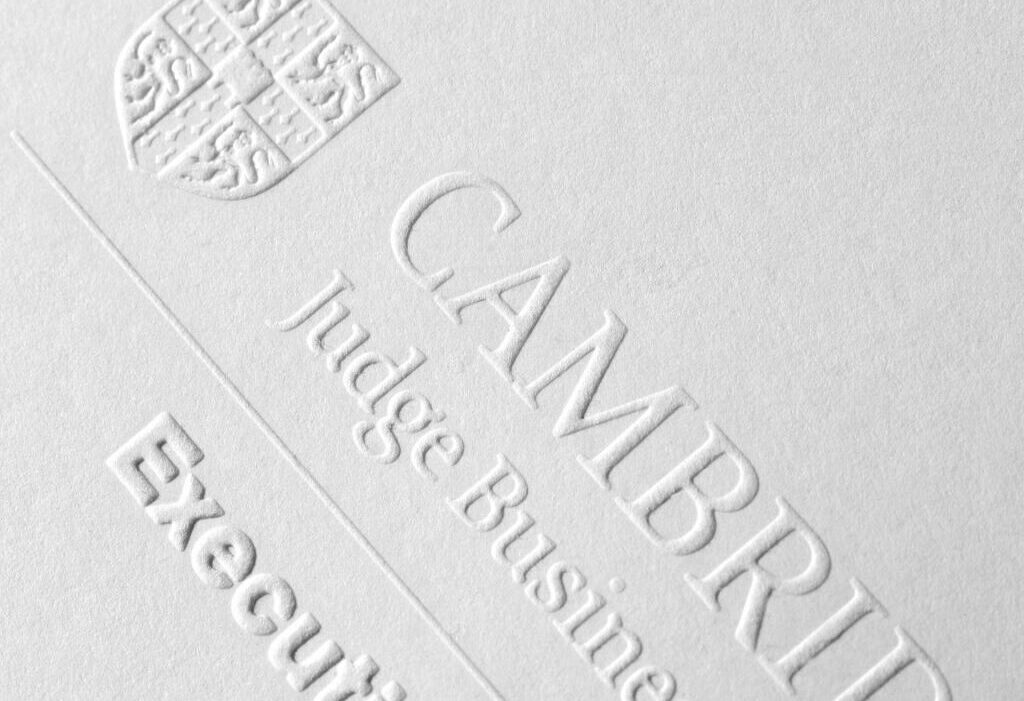

Embossing

In the printing industry, Embossing refers to a method of pressing an image into paper or cardstock to create a three-dimensional design. Text, logos and other images can all be formed by the embossing method. Embossing results in a raised surface, with the design higher than the surrounding paper area. Embossing provides a look of high quality and elegance.

Example of Embossing – business cards, certificates, and stationery

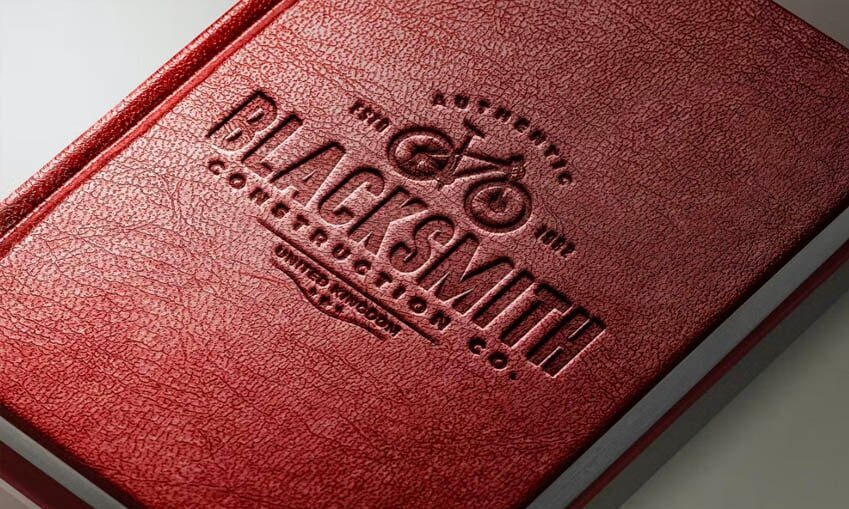

Debossing

This is (not surprisingly) the opposite of embossing. Debossing is when an image (logo, text, etc.) is imprinted into your print piece, creating a depressed effect. Just like embossing, you can choose to leave the debossed area untouched or fill it in with ink or foil stamping. Large fonts and bold artwork design are best for debossing, rather than fine lines or lettering.

Example of Debossing – product packaging, leather good, and the use of large logos on paper and publications

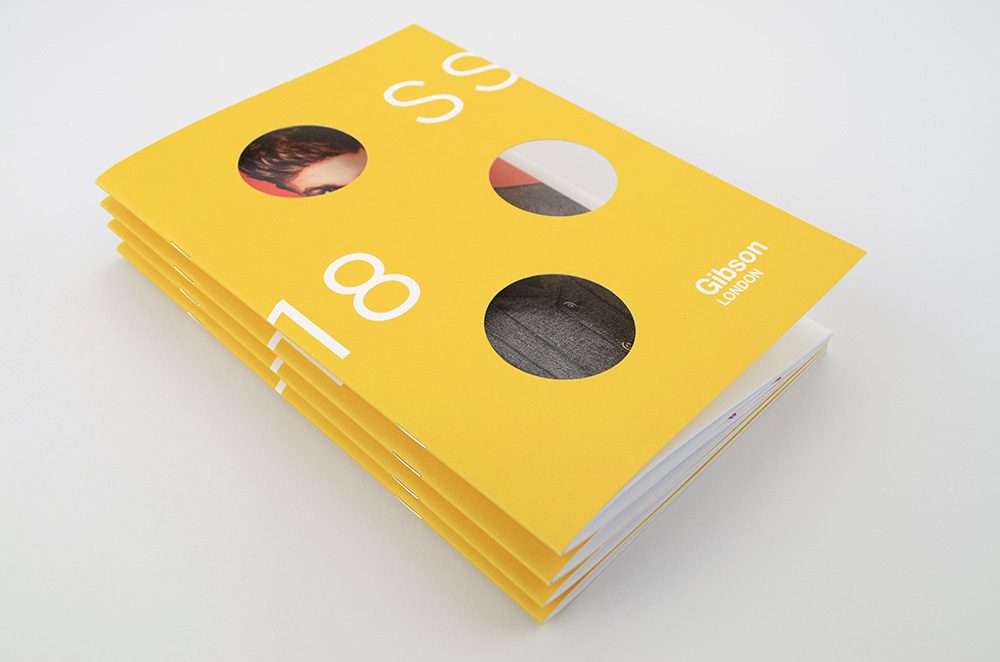

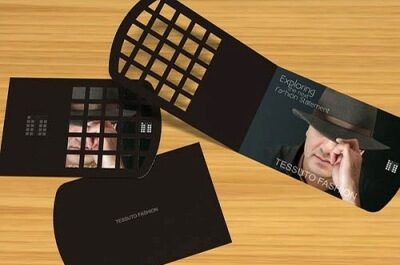

Die-cutting

In the world of printing, a Die refers to a thin, razor-sharp steel blade that has been formed into a specific shape or pattern (sort of like a heavy-duty cookie-cutter). Consequently, Die-Cutting refers to the act of using this sharp die to cut paper, cardstock, label stock, or other substrates into various shapes. This an automated operation and it allows multiple pieces of the same shape to be created in an efficient and uniform manner.

Example of Die-cutting – cut shapes in leaflets and stationery, branding logo cut-outs, labels and folders

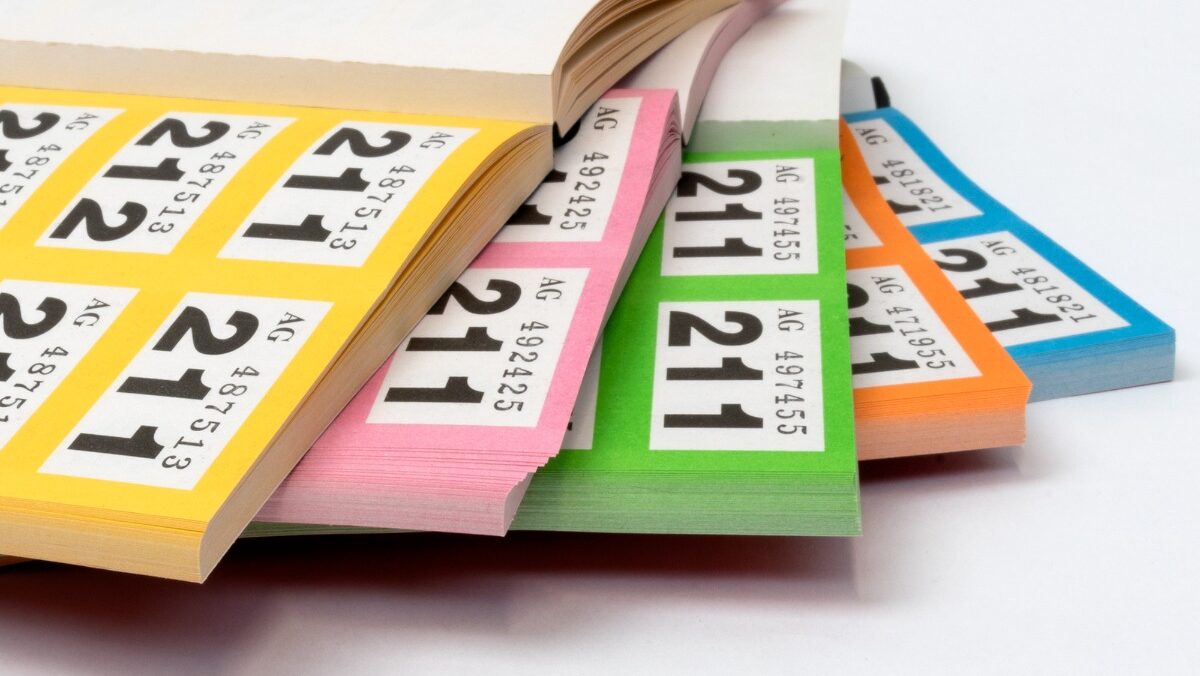

Perforation

this process is used in the printing industry to allow easy separation of two sections of the material, such as allowing paper to be torn easily along the line. It can be used instead of creasing: perforation makes extra-thick materials to be folded in a straight manner with no paper cracks.

Example of Perforation – tickets, vouchers, forms, and flyers and leaflets

Punching

In printing, the term ‘Drilling’ refers to the process of creating round holes in paper using a rotating bit. Unlike a manual punch, which presses holes through one or a few sheets of paper, the drilling operation uses a specialized machine with sharp hollow bits to bore through thick stacks of paper. A paper drill produces very clean and precisely-placed holes. Also, drilling saves valuable time because it can penetrate through hundreds of sheets at once. It can also be set up to create multiple holes in one pass.

Example of Punching – labels, tags, reports, personal organisers/calendars, and notepads

Spot UV

UV Coating is a tough clear-coat applied over printed matter. It is applied in liquid form, then exposed to Ultra-Violet (UV) light which bonds and dries it instantly…hence its name ‘UV Coating’. Spot UV refers to the application of this UV Coating to a specific area (or areas) of a printed piece rather than coating the entire surface. Used primarily as a design technique, Spot UV is a creative way to add depth and contrast through varying levels of sheen and texture. Spot UV is the ultimate in deluxe printing techniques; it provides a unique and exceptional way to introduce yourself and is the perfect way to make a lasting impression.

Example of Spot UV – business cards, labels, luxury promotional items, envelopes, and folders

Hand Finishing

This is when we are completing a job to the client’s specific requirements. It includes packing, assembling, attaching, inserting, collating and gluing. Some Hand Finishing options include: bagging, double-sided taping, drilling, envelope counting, glue dots, mailing, etc…

Example of Hand Finishing – promotional merchandise, packing, assembly, and collections

How can we help?

At Graphic Arts Group, we offer much more than just ‘ink on paper’ – Printing is our business and we’re committed to ensuring your projects are consistently produced to the highest of standards.

Our team also have a high level of experience servicing design studios, advertising agencies, local authorities, small businesses and large corporations, so you can reply on us as your communications partner – no matter the size of your project.

Constantly investing in the latest technology, we understand the importance of following modern printing techniques, providing our clients

We are your complete print and communications partner.

Contact us today to have a chat about your printing needs!