Print production – A guide to finding what you want

There are so many elements of print production that it’s hard to know what you’re asking for when you choose a product. You know what you want the end product to look like, but you’re unsure how to ask for it because you don’t understand the technical jargon used in print production.

Hopefully this guide will help you navigate your way through the world of printing as you try to make the best of your budget.

This is the second in a three-part series where we’ll have a look at some of the processes and materials in print production and break it all down for you.

Part 1 – Printing processes

Part 2 – Binding processes (you’re reading this one now!)

Part 3 – Speciality Finishing

Part 2 – Binding

In its most simple terms, print binding is the fastening together of individual sheets of paper in order to create materials like catalogues, booklets, magazines, etc.

The binding process usually consists of stitching, gluing, stapling, or punching holes to connect pages with wire or plastic. When you bind pages together you create a spine on one edge where the pages are connected. This ensures that each page is secured together to create a durable printed product.

Have a look in more detail at the different methods of biding and a few examples of when you would use each.

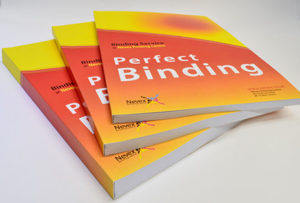

Perfect Binding

The pages and cover are glued together at the spine and the other three sides of the book are trimmed as needed to give them clean, ‘perfect’ edges. This is widely used for soft cover book binding because the spine uses a strong, yet flexible, thermal glue. This gives the product a professional appearance at a relatively low cost.

PUR binding is a form of perfect binding that uses a special Polyurethane Reactive (PUR) adhesive. This is the most durable form of perfect binding as the glue is superior to that used in traditional perfect binding. Bottom line: if quality and durability are important to you, always select PUR binding when you have the choice.

Example of Perfect Binding – softcover books found in bookshops

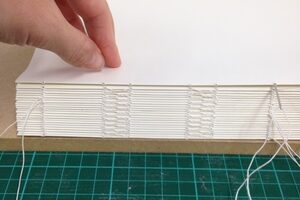

Section Sewn Binding

The most secure binding method. Pages are folded together into sections. Each section is sewn into the following section along the spine. The spine is glued together for extra support and the cover attached. A Section Sewn book, regardless of page count, will be able to lay flat.

Example of Section Sewn Binding – soft and hardcover books that need to withstand more wear and tear

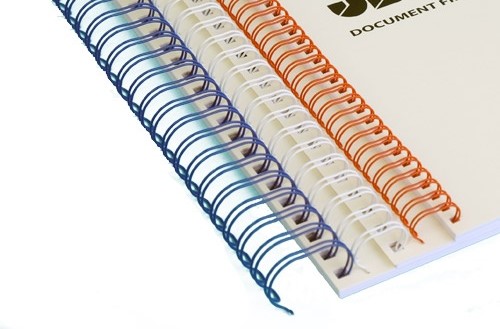

Wire-O Binding

Also known as Twin Loop, Double-Loop, Double-O, Duo-Wire or simply Wire Binding, this method utilises pre-formed pairs of wire loops that run along a C-shaped unit. These wire loops are inserted through holes that have been punched through the book’s cover and pages. The loops are then crimped closer together until they form a perfect circle, thus securing the cover and pages as an assembly, yet allowing them to open freely.

Example of Wire-O Binding – Cookbooks, journals, workbooks and instruction manuals

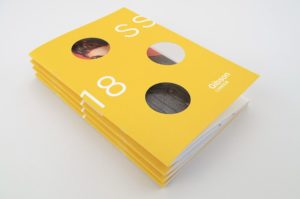

Saddle Stitch Binding

This uses wire staples to join the pages and cover at the spine. The staples pass through the spine’s folded crease from the outside and are clinched between the centremost pages. Though relatively simple, the result is a very professional looking document.

Example of Saddle Stitch Binding – catalogues, manuals, booklets, programs, and multi-page brochures as well as many more!

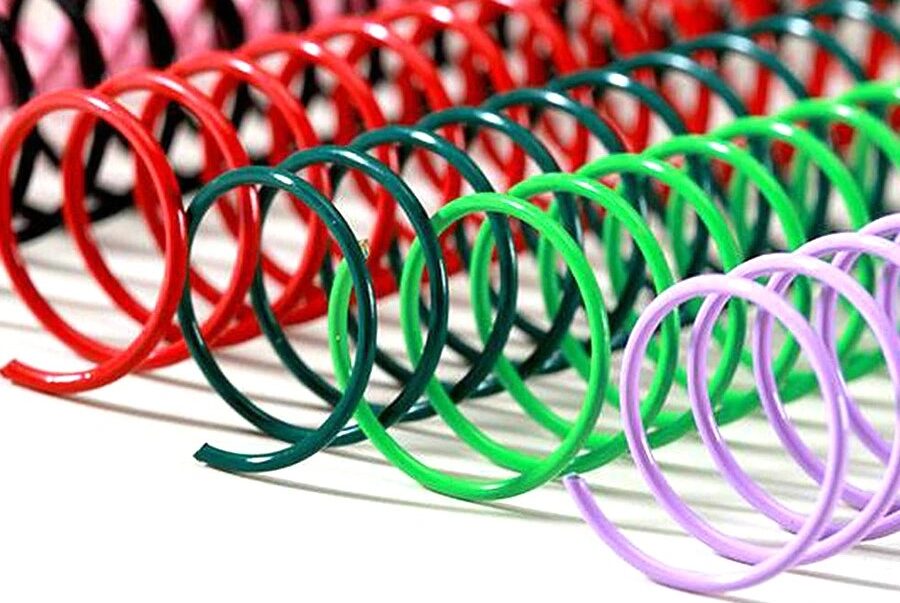

Spiral Binding

Interchangeably referred to as Coil Binding, this popular method joins the pages and cover of a book using a durable plastic coil. The coil is inserted and twisted through small holes punched along the spinal edge of the book’s cover and pages.

One of the primary benefits of a spiral bound book is that the pages can be opened a full 360 degrees. This allows an open book to fold back upon itself and yet remain flat, so it stays open for each reference and takes up minimal room on a desk or table.

Example of Spiral Binding – reports, sales presentations, proposals, directories, and maintenance guides

How can we help?

At Graphic Arts Group, we offer much more than just ‘ink on paper’ – Printing is our business and we’re committed to ensuring your projects are consistently produced to the highest of standards.

Our team also have a high level of experience servicing design studios, advertising agencies, local authorities, small businesses and large corporations, so you can reply on us as your communications partner – no matter the size of your project.

Constantly investing in the latest technology, we understand the importance of following modern printing techniques, providing our clients

We are your complete print and communications partner.

Contact us today to have a chat about your printing needs!